Vacuum Bag Sealer-Machines are becoming increasingly popular in household and commercial settings. These machines offer a convenient and efficient way to preserve and store food items, making them an essential appliance for any kitchen. But have you ever wondered about the inner workings of these machines? In this blog post, they will explore the functionality of vacuum bag sealer machine and how they work to vacuum and sea food items. By the end of this post, you will better understand the technology behind vacuum bag sealers and how they can benefit you in your daily life. So, let’s dive in and discover the world of Vacuum Bag Sealer-Machines!

Understanding the Basics of Vacuum Bag Sealer-Machines

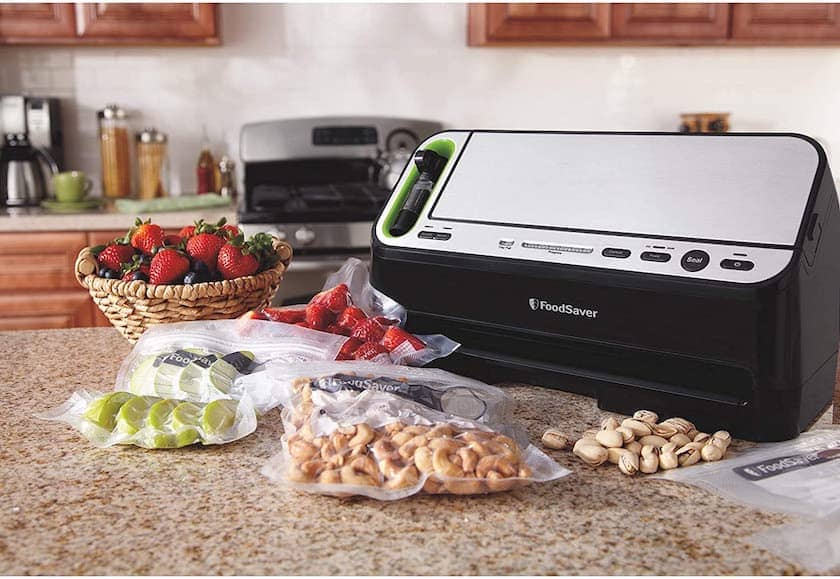

Vacuum Bag Sealer-Machines embody a sophisticated mechanism designed to extract air from a plastic bag and then securely seal it. This process is instrumental in preserving the quality of food items by significantly reducing the oxygen level within the packaging, thus hindering the growth of bacteria, mound, and yeast that contribute to spoilage and deterioration. The principle of operation begins with placing the food item inside a specially designed sealer bag. The open end of the bag is then inserted into the machine.

Upon activation, the machine extracts the air from the bag through a vacuum pump system. Following the air extraction, the machine’s sealing function activates, utilising heat to melt the bag’s open edge, thereby creating an airtight seal. This dual-action process extends the shelf life of food products and maintains their flavor and nutritional value over time. The effectiveness of Vacuum Bag Sealer-Machines in preserving food has made them indispensable in both domestic kitchens and commercial food production environments.

The Different Types of Vacuum Sealer Machines

Vacuum sealer machines are categorized into several varieties to cater to the diverse needs of users and industries. External vacuum sealers, often chosen for household applications, provide a straightforward and economical option for those looking to extend the shelf life of their food with minimal fuss. For larger or commercial operations, chamber vacuum sealers are the go-to choice, capable of handling high volumes of sealing efficiently and uniformly. These machines encase the entire bag within a vacuum chamber, allowing for precise control over the vacuum process and a higher-quality seal.

Meanwhile, portable and handheld sealers offer unmatched convenience for individuals with space constraints or needing sealing capabilities on the move. Each type of machine embodies specific features designed to fulfil particular requirements, whether for light domestic use or heavy-duty commercial purposes. Understanding each model’s unique advantages and limitations is key to making an informed decision that aligns with the user’s operational scope and objectives.

The Versatility of Vacuum and Seal Machine

The adaptability of vacuum and seal-machines extends well into numerous sectors, underscoring their utility beyond simple food preservation tasks. In the commercial realm, these devices find applications in the meticulous packaging of pharmaceutical products, ensuring they remain uncontaminated and secure. Electronic components, vulnerable to damage from moisture, are effectively protected, illustrating the machines’ capability to safeguard sensitive materials.

Furthermore, their role in preparing items for sterilization highlights their critical function in maintaining hygiene and safety standards in medical and research settings. The flexibility to accommodate various materials and package sizes enhances their utility, making vacuum and seal machine indispensable across multiple industries. The confines of culinary preservation do not constrain their application but extend to any context where an airtight seal could mitigate risk and prolong product integrity.

The Advantages of Using a Vacuum Heat Sealer Machine

The adoption of a vacuum heat sealer machine confers multiple advantages, notably in the realm of securing a robust seal. Through targeted heat and pressure, these machines melt the edges of plastic bags, forging a seal that stands resilient against potential breaches. This sealing technique is particularly effective for safeguarding the integrity of perishable goods and delicate products, ensuring their preservation under optimal conditions.

Moreover, the strong bond formed by the heat sealing process is ideally suited for items destined for transportation or extensive storage periods, providing a reliable defense against the elements and preventing the ingress of contaminants. The capacity of Vacuum Heat Sealer Machine to deliver such a durable and protective seal demonstrates their value in maintaining product quality and extending lifespan, embodying a critical asset for entities across various sectors seeking to enhance their packaging efficacy.

Factors to Consider When Choosing a Vacuum Bag Sealer-Machine

In the selection process for a Vacuum Bag Sealer-Machine, several critical aspects warrant attention to ensure the chosen device aligns with the user’s requirements. The volume and frequency of sealing operations are paramount; machines designed for high-volume commercial use may not be suitable for lighter, domestic applications. Conversely, a machine that is too basic may not meet the demands of a busy retail environment. The nature of the products to be sealed plays a significant role, as certain machines may offer specific features suited to delicate or bulky items.

Space availability is another factor; some models are compact and suitable for tight spaces, whilst others might require a dedicated area. Compatibility with various bag materials and sizes ensures versatility in use, and the efficiency of the seal is crucial for maintaining the integrity of the sealed items. Evaluating these factors carefully facilitates the identification of a Vacuum Bag Sealer-Machine that not only meets the immediate needs but also accommodates future requirements, enhancing the utility and longevity of the investment.

Tips for Optimising the Use of Your Vacuum Sealer Machine

Maximising the efficiency of a vacuum sealer machine involves adopting practices that enhance its functionality whilst ensuring the preservation quality of the packaged items. The following pointers can aid in optimising the operation of these machines:

– Regularly check the seal integrity:

Periodic examinations of the seals created by the machine can detect any inconsistencies early, allowing adjustments to be made before they compromise the vacuum integrity.

– Utilise appropriate bag sizes:

Selecting bags that comfortably accommodate the items without excess material can improve vacuum efficiency and reduce waste. Additionally, using bags that are slightly larger than needed can facilitate re-sealing after initial use.

– Pre-freeze liquids and moist items:

Pre-freezing before vacuum sealing can prevent moisture from affecting the sealing process and ensure a stronger vacuum for items with high liquid content.

– Distribute contents evenly:

When preparing bags for sealing, ensure the contents are distributed evenly. This aids in achieving a uniform vacuum and seal, which is particularly important for bulky or irregularly shaped items.

– Keep the machine clean:

Ensuring the machine, especially the sealing bar and vacuum chamber, is clean and free from debris can prevent operational issues and maintain the quality of the seal.

– Monitor the machine’s temperature:

During extensive use, monitoring the machine for signs of overheating can prevent damage to the machine and the seal quality. Allowing the machine to cool down between batches can extend its lifespan.

– Calibrate the vacuum level:

If the machine has adjustable vacuum settings, calibrating the vacuum level according to the sealed product type can enhance preservation by tailoring the vacuum intensity to the item’s requirements.

Adopting these practices can significantly enhance the efficiency and reliability of a vacuum sealer machine, ensuring items are preserved in optimal conditions whilst maximising the machine’s operational longevity.

Troubleshooting Common Issues with Vacuum Bag Sealer-Machines

Encountering operational difficulties with Vacuum Bag Sealer-Machines is common, and these challenges often have straightforward solutions. Among the issues frequently reported are partial seals, fluctuating vacuum levels, and instances of the machine becoming excessively hot during use. Initial steps to rectify such problems include:

- Examining the machine for any obstructions that might impede its function.

- Ensuring the cleanliness of the sealing bar to maintain a consistent seal.

- Confirming that the bags are positioned correctly within the machine to facilitate optimal vacuum and sealing.

These measures often suffice in resolving the majority of operational concerns. However, when faced with more intricate difficulties, it is prudent to refer to the manufacturer’s guidance or seek expertise from professionals. Such an approach ensures that the Vacuum Bag Sealer-Machine continues to operate efficiently, reducing downtime and maintaining the integrity of the sealing process.

The Future of Vacuum Sealing Technology

The trajectory of vacuum sealing technology is set to be marked by significant strides in enhancing both operational efficiency and the environmental footprint of these machines. With ongoing research and development, the sector anticipates the introduction of more sophisticated vacuum pumps that promise to elevate the effectiveness of air extraction, thereby optimising the sealing process further. Concurrently, a shift towards utilising resilient and eco-friendly materials is expected, aligning with the growing demand for sustainable packaging solutions.

Additionally, integrating Internet of Things (Iota) connectivity into vacuum sealer machines is poised to revolutionise how they are operated and monitored, offering unprecedented control and insight into packaging processes. This evolution towards smarter, more sustainable, and highly efficient vacuum sealing solutions underscores the industry’s commitment to meeting the needs of the future, with a keen eye on minimising environmental impact and enhancing user convenience. These forthcoming advancements herald a new era for vacuum sealing technology, promising to redefine packaging standards across various sectors.

Mastering the Maintenance of Your Vacuum Sealer Machine

Ensuring the longevity and optimal performance of Vacuum Bag Sealer-Machines necessitates a diligent approach to maintenance. Fundamental to this is a routine check of the machine’s components, particularly the sealing bar and vacuum chamber, for any signs of wear or accumulation of debris. Such inspections help in identifying issues that could impair functionality. Cleaning the machine after each use is also imperative; this involves wiping down the sealing bar and vacuum chamber to remove any residual particles or moisture that could compromise the sealing process.

Additionally, it is recommended to regularly inspect the vacuum pump and replace any worn-out parts or seals to maintain efficient operation. Keeping the machine’s exterior clean and dust-free contributes to its operational efficacy and prolongs its lifespan. Implementing a scheduled maintenance routine based on the manufacturer’s guidelines aids in pre-empting potential malfunctions. Observing these practices ensures that the Vacuum Bag Sealer-Machine remains a reliable tool for food preservation and packaging, facilitating its continuous operation without significant downtime or degradation in performance.

Mastering Vacuum Bag Sealer Maintenance

Achieving proficiency in maintaining vacuum bag sealer-machines is integral to ensuring their longevity and optimal performance. A comprehensive understanding of the operational mechanics and care protocols is essential. Engaging with contemporary maintenance methodologies and materials can significantly elevate the functionality and endurance of these machines. Participation in knowledge-sharing platforms, such as forums or workshops, is advisable for acquiring advanced insights and competencies.

Furthermore, commitment to the upkeep of these devices through regular inspections for wear and the timely replacement of parts as necessary is crucial. Keeping the vacuum chamber and sealing bar pristine is paramount to prevent operational hindrances and sustain the machine’s efficiency. Adherence to the manufacturer’s recommended maintenance schedule is vital in preserving the machine in prime working order. Through diligent care and informed maintenance practices, users can ensure their Vacuum Bag Sealer-Machine remains a dependable component of their packaging processes.

FAQS

1. What distinguishes a chamber vacuum sealer from an external vacuum sealer?

A chamber vacuum sealer encases the entire bag within a vacuum chamber, offering precise control over the vacuum process and a higher-quality seal suitable for commercial applications. In contrast, an external vacuum sealer, ideal for household use, vacuums air from the bag outside the machine, providing a straightforward and economical option for food preservation.

2. Can vacuum sealer machines handle liquids?

Yes, these machines can handle liquids, but pre-freezing liquid items before sealing is advisable. This prevents moisture from interfering with the sealing process and ensures a stronger vacuum is achieved, maintaining the integrity of the seal.

3. Are Vacuum Bag Sealer Machines compatible with all types of plastic bags?

No, these Vacuum Bag Sealer Machine typically require specially designed sealer bags. These bags are made to withstand the vacuum process and the heat sealing mechanism. Compatibility varies among different models, so verifying the types of bags a machine can accommodate is essential.

4. How does vacuum sealing extend the shelf life of food?

Vacuum sealing extends food shelf life by reducing oxygen levels in the packaging, which slows down the growth of bacteria, mound, and yeast that contribute to food spoilage. This process also retains the food’s flavor and nutritional value over time.

5. Is maintenance of Vacuum Bag Sealer-Machines complex?

Maintenance involves routine checks for signs of wear, regular cleaning after use, and ensuring the sealing bar and vacuum chamber are debris-free. Following the manufacturer’s maintenance schedule and promptly replacing worn parts help maintain the machine’s efficiency and prolong its lifespan.

Conclusion

In summary, vacuum bag sealer machines are an innovative solution, revolutionising how food items and other perishables are preserved and stored. From domestic kitchens to commercial settings, the versatility and efficiency of these machines are unmatched, catering to a broad spectrum of packaging needs. Through exploring the functionality, types, and maintenance of vacuum sealer machines, it becomes evident that these devices offer substantial benefits in prolonging the shelf life of products, maintaining their quality, and offering a robust defense against spoilage.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |

| Other Good Articles to Read |

| Skank Blogs |

| Unreal Blogs |

| Tba Blogs |

| All City Forums |

| Dany Blogs |

| Refuge Blogs |

| The Music Blogs |

| Key Forums |

| The Big Blog Theory |

| Joe Blogs |

| Blogs 4 Me |

| Blogs Emon |

The post Exploring the Functionality of Vacuum Bag Sealer Machine appeared first on Blogs Unplugged.

from Blogs Unplugged https://ift.tt/DcS0tJg

via IFTTT

0 comments:

Post a Comment